The assembly line of a Tricycle Motorcycle refers to a production line that assembles various components of a tricycle. This production line covers all key components of a three wheeled motorcycle, including the frame, engine, transmission system, suspension system, braking system, body shell, etc.

The Gasoline Tricycle assembly line usually includes the following processes.

The first step is the assembly of the frame. The frame is the basic component of a three wheeled motorcycle, which carries the weight of the entire vehicle and other components. In the assembly of the frame, workers need to weld, connect, and adjust various components according to the design requirements to ensure the strength and stability of the frame.

Next is the installation of the engine. The engine is the power source of a Three wheeled motorcycle equipment, which transmits power to the wheels through the transmission system to drive the motorcycle. In the engine installation process, workers need to connect the engine to the frame and install accessories such as the fuel system and electronic control unit.

The assembly of the transmission system is the next important process. The transmission system includes clutches, transmissions, and chains. The clutch controls the power transmission between the engine and the transmission, and the transmission controls the forward speed of the vehicle. In the assembly of the transmission system, workers need to accurately install and adjust these components to ensure the reliability and stability of the transmission system.

The assembly of the suspension system is also an important process in the assembly line of three wheeled motorcycles. The suspension system includes components such as front and rear shock absorbers and suspension bridges for motorcycles. In the assembly of the suspension system, workers need to connect these components to the frame, adjust and calibrate them to provide stable suspension and comfortable riding experience.

The assembly of the braking system is also crucial. The braking system can ensure the safety of motorcycle driving, including front and rear brake pads, brake discs, brake pipelines, and brake fluid. In the assembly of the braking system, workers need to correctly install these components and ensure that the braking effect meets the design requirements through system pressure testing and adjustment.

Finally, the assembly of the body shell. The body shell is the exterior part of a three wheeled motorcycle, usually made of plastic or metal materials. In the assembly of the body shell, workers need to assemble the various components of the shell, and carry out surface treatment and spraying to make the entire body look beautiful and meet market demand.

The above are just some typical processes in the assembly line of a three wheeled motorcycle. In actual production, there are many other details to be considered, such as the assembly, wiring and commissioning of the electrical system, as well as the final vehicle inspection and commissioning.

In short, the three wheeled motorcycle assembly line is a production line that assembles various components according to the process flow, ensuring that the final product meets quality requirements and design standards. Only through precise processes and strict testing can safe, reliable, and high-performance tricycles be produced.

| Brand Name | ZONLON |

| Component Name | motorcycle cable |

Tricycle Motorcycle assembly line equipment: A Comprehensive Overview

The production of tricycle motorcycles involves a complex and highly specialized manufacturing process. To ensure efficiency, precision, and consistency, modern assembly lines rely on advanced equipment designed specifically for tricycle motorcycle assembly. This article explores the key components of tricycle motorcycle assembly line equipment, their functions, and the role they play in streamlining production.

1. Introduction to Tricycle Motorcycle Assembly Lines

Tricycle motorcycles, which feature three wheels for enhanced stability, are widely used for commercial and personal transportation. The assembly process requires a combination of manual labor and automated machinery to ensure high-quality output. Assembly line equipment is categorized into several stages, including frame fabrication, component installation, quality control, and final testing.

2. Key Equipment in Tricycle Motorcycle Assembly Lines

2.1 Frame Welding and Fabrication Equipment

The assembly process begins with the construction of the tricycle frame, which serves as the foundation for all other components. Key equipment includes:

Robotic Welding Machines: Automated welding arms ensure precise and consistent welds, reducing human error.

Jigs and Fixtures: Customized holding devices secure frame parts in place during welding and assembly.

CNC Cutting Machines: Used to cut and shape metal sheets for frame components with high accuracy.

2.2 Engine and Transmission Installation Systems

The engine is the heart of the tricycle motorcycle, and its installation requires specialized equipment:

Engine Mounting Stations: Adjustable platforms that align the engine correctly with the frame.

Torque Wrenches and Automated Fastening Tools: Ensure bolts and screws are tightened to exact specifications.

Conveyor Belts: Transport engines and transmissions to different assembly stations efficiently.

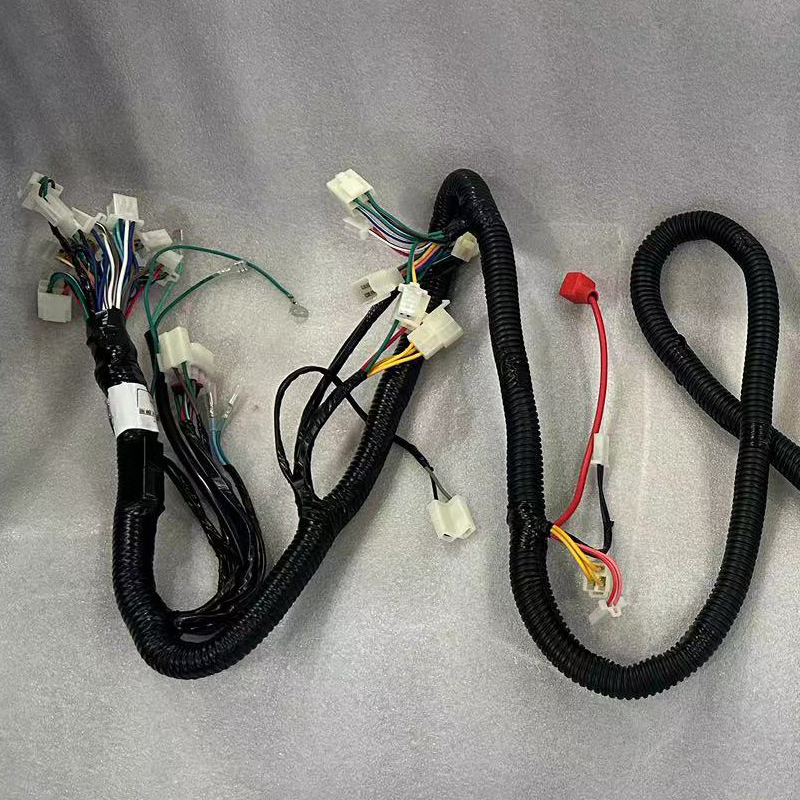

2.3 Electrical and Wiring Assembly Equipment

Modern tricycle motorcycles feature complex electrical systems, requiring:

Wire Harness Assembly Machines: Automate the cutting, stripping, and crimping of wires.

Testing Stations: Verify electrical connections, battery performance, and lighting systems before final assembly.

2.4 Body Panel and Fairing Installation

The exterior panels and fairings are installed using:

Panel Pressing Machines: Ensure panels fit seamlessly onto the frame.

Adhesive Application Robots: Apply sealants and adhesives for waterproofing and durability.

2.5 Wheel and Suspension Assembly

Tricycle motorcycles require robust suspension systems due to their three-wheel design:

Wheel Alignment Systems: Ensure all wheels are properly aligned for stability.

Suspension Testing Rigs: Simulate road conditions to verify shock absorber performance.

2.6 Painting and Coating Systems

A high-quality finish is essential for both aesthetics and corrosion resistance:

Automated Paint Booths: Provide even coating with minimal overspray.

UV Curing Machines: Speed up the drying process while ensuring durability.

2.7 Final Assembly and Quality Control

Before leaving the factory, each tricycle motorcycle undergoes rigorous testing:

Dynamometer Testing: Measures engine performance under simulated riding conditions.

Brake Testing Stations: Ensure braking systems meet safety standards.

Final Inspection Lines: Human inspectors and automated scanners check for defects.

3. Automation in Tricycle Motorcycle Assembly

Automation has revolutionized motorcycle manufacturing by improving speed and consistency. Key technologies include:

Industrial Robots: Handle repetitive tasks such as welding, painting, and component placement.

Computer Vision Systems: Detect defects in real-time during assembly.

IoT-Enabled Monitoring: Tracks equipment performance and predicts maintenance needs.

4. Challenges in Tricycle Motorcycle Assembly

Despite technological advancements, manufacturers face challenges such as:

High Initial Investment: Advanced machinery requires significant capital.

Skilled Labor Shortage: Operators must be trained to handle automated systems.

Supply Chain Dependencies: Delays in component deliveries can disrupt production.

5. Future Trends in Assembly Line Equipment

The future of tricycle motorcycle assembly lies in:

AI-Driven Optimization: Machine learning algorithms will enhance production efficiency.

Modular Assembly Lines: Flexible setups that allow quick adaptation to different tricycle models.

Sustainable Manufacturing: Energy-efficient equipment and recyclable materials will reduce environmental impact.

6. Conclusion

Tricycle motorcycle assembly line equipment plays a crucial role in ensuring high-quality, efficient production. From robotic welding to automated quality control, each piece of machinery contributes to a streamlined manufacturing process. As technology evolves, assembly lines will become even more advanced, further improving productivity and reducing costs.

By understanding the key components and trends in assembly line equipment, manufacturers can optimize their production processes and meet the growing demand for tricycle motorcycles worldwide.

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.